Custom Metal Shaping & Forming: From Prototype To Mass Production All Under One Roof

From Raw Sheet To Resilient Products and Parts

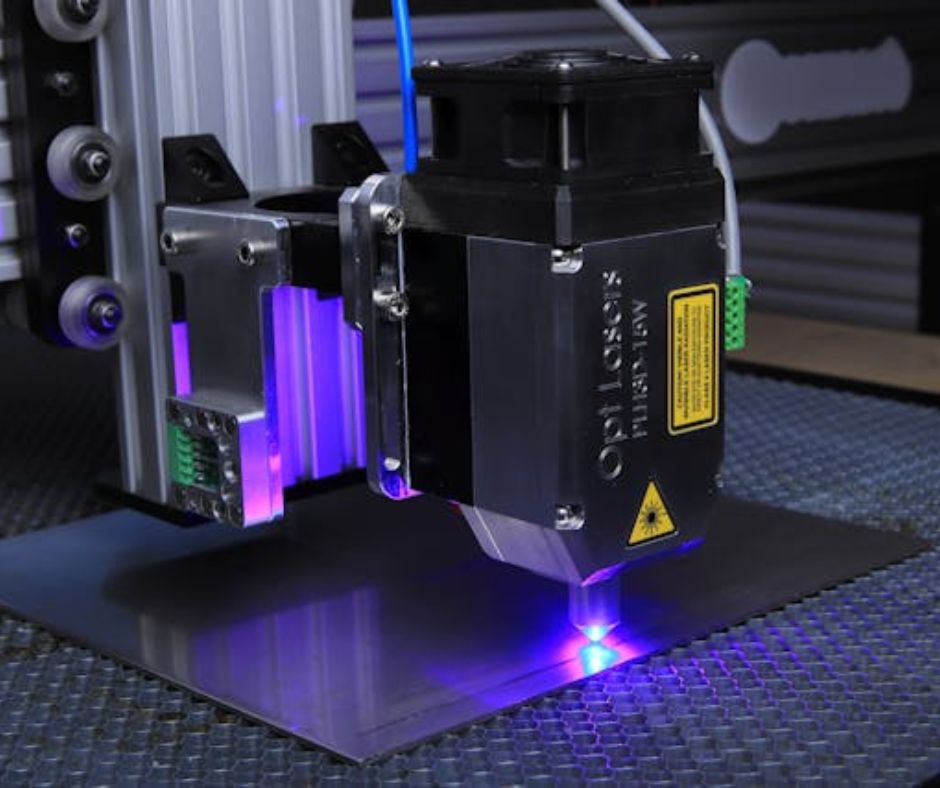

Your product’s geometry should never be limited by a fabricator’s available tools. At Datsons Engineering we pair high-precision laser cutting, in-house die & tool design, and presses up to 60 tons so that we can shape, bend, roll and join metals to turn your ideas to reality.

When you hand us CAD drawing or even a sketch on a napkin, you’re tapping into our 50 years of experience of bending metals on our own terms. From custom die tools for mass production to specialised laser cutting for millimeter precision Datsons Engineering is ever-ready to offer you both – 5 prototypes on your desk within 48 hours or 50000 tested parts for a nationwide rollout.

No Geometry Is Off-limits

Years in Business

Projects

Active Customers

Indian States Served

The Problem

It’s Never About If We Can Do. It’s Always About How – No Matter How Complex Your Vision Is

Zero Tolerance-Drift Even When You Ramp Up Production

Never worry about tolerance drift at scale. With advanced computer aided laser cutting limit tolerance to +-0.1mm. Even for traditional throughput, our hydraulic presses powered by skilled workers maintain strict tolerance and adherence to standards.

Prototyping Bottlenecks? Not With Us

Want place a <50 piece prototype order. We’re up for it. For most projects we take 48 hours to at least send you a minimum viable product for you to test, iron-our inconsistencies and request for modification on an overall basis.

In-House Die Tool Manufacturing For Rapid Launch

In-house wire-cut & VMC toolroom means dies, gauges and fixtures are born next door to the forming bay. By keeping the forge this close to the forming bay, we cut weeks off die-shop lead-times.

Services Offered Under Shaping & Forming

At Datsons Engineering Shaping and Forming isn’t just an initial task – rather the very foundation of building something sacred to the client. Explore the processes and services involved in this:

From The Desk of CEO

Shaping and forming forms the basis of any fabrication work. It’s the soul of your product – the very spinal chord. It should be done with precision, and utmost care.

– Sourish Dutta

Laser profiling

Up to 6 mm (MS) and 4 mm (SS)

Press-brake forming

up to 2 500 mm (±0.2° angle)

Roll & stretch forming

For Curved Profiles

Custom die creation

With Wirecutting / VMC / Milling & Shaping Machine

Joining Options

Welding, riveting, nut-bolting and more

Hydraulic/mechanical pressing

Upto 60 tons

Industries and Use-Cases

Real-world applications where our shaping and forming capabilities solve complex industrial challenges.

Tolerances & Capabilities

Explore the technical limits of our shaping and forming operations, defined by accuracy, repeatability, and robust in-house control.

Showcase your most prominent testimonials

This sub headline is a text block global style that is larger and bolder.

“This is testimonial placeholder text which will be replaced by your real testimonials. Dignissim lacus massa mauris enim mattis magnis senectus montes mollis semper blandit nibh aliquam metus morbi vivamus magnis congue pharetra gravida pharetra magna.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper pharetra torquent auctor metus felis nibh velit. Natoque tellus semper taciti nostra semper pharetra montes habitant congue. Lorem ipsum amet elit morbi dolor tortor.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper auctor pharetra torquent metus felis nibh congue gravida magna inceptos vivamus eget mollis nostra ullam.”

Customer Name

Business Name

Let Your Vision Meet Our Dies and Laser

No vision is “infeasible” for us, no tolerance requirement is tighter for us, no deadline is non-achievable for us. At Datsons, shaping and forming isn’t just a capability—it’s the language we’ve spoken since 1976. You bring the concept. We’ll bend the metal, build the tools, and prove it in parts.

Schedule an AppointmentCall for Service Today