Custom Tooling: We Don’t Ask If It’s Manufacturable. We Ask When You Need It Done.

Lifetime Tools, No Hidden Maintenance — All On Us

That odd bend? That unforgiving gauge of stainless? We’ve built custom tools and dies that press them clean, run after run. From half-inch inserts to 2-foot assemblies — same team, same roof, same 0.1 tolerance. Welding talks to tooling, CAD talks to floor, no handoffs lost in translation. You pay once. We design, build, maintain. The die stays ours. The performance stays yours.

No tolerance for poor tolerances

Years in Business

Projects

Active Customers

Indian States Served

Our Solutions

If your part gives most dies a panic attack, it probably belongs here.

We Don’t Judge Your Geometry. We Tool It.

Sharp corners, compound curves, material that refuses to behave — we’ve seen worse. We design tools for non-standard shapes that other shops sidestep. From simulation to ready-run dies, everything is built in-house, tolerance-tight, and mass-production-ready. The wilder the geometry, the more it belongs here.

One Tool. Ten Thousand Runs. Still On Spec.

One-time tool cost, infinite mileage. Our dies are built for long-haul production: no tapering precision, no downtime drama. Whether you’re pressing thin stainless or thick mild steel, the tool just works. Day shift, night shift, again and again. And if something does go off, we fix it. No paperwork.

When Your Tool Guy Knows Your Welder By Name

Our design, welding, and tooling teams share the same floor — not folders. When something needs fixing, it’s solved over a conversation, not a call. That’s how a die goes from CAD to production without ever losing tempo.

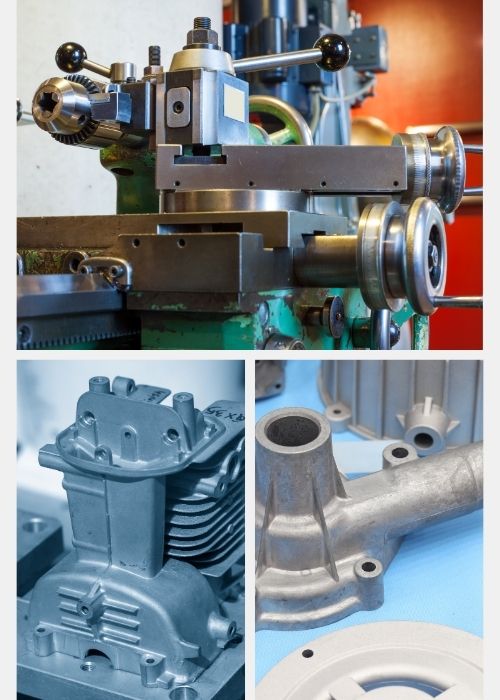

Services Offered Under Shaping & Forming

Datsons Engineering is capable of handling all the major kinds of Welding – including computer operate Laser Welding:

Custom Tool Design & Development

Complex parts, tight tolerances, custom dies – built completely in-house.

Tooling for Mass-Scale Production

Dies that survive scale, cycles, abuse — and stay in spec.

Integrated In-House Tool + Weld Systems

Toolmakers and welders, same team. Fewer errors. Faster builds.

Technical Specifications

Tolerance Range

±0.1 mm maintained across repeated operations and long production runs.

Tool Size Range

From ½ sq inch inserts to large tools of 2 ft × 2 ft.

Bending Capability

Up to 8 ft bending length; as thin as 0.3 mm stainless.

Workflow Speed

CAD to press-ready tool with full in-house design and build.

Tooling Lifespan

One-time tool cost with lifetime repair, handled by us.

Production Type

Mass-scale, high-repetition production with minimal tool fatigue.

Showcase your most prominent testimonials

This sub headline is a text block global style that is larger and bolder.

“This is testimonial placeholder text which will be replaced by your real testimonials. Dignissim lacus massa mauris enim mattis magnis senectus montes mollis semper blandit nibh aliquam metus morbi vivamus magnis congue pharetra gravida pharetra magna.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper pharetra torquent auctor metus felis nibh velit. Natoque tellus semper taciti nostra semper pharetra montes habitant congue. Lorem ipsum amet elit morbi dolor tortor.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper auctor pharetra torquent metus felis nibh congue gravida magna inceptos vivamus eget mollis nostra ullam.”

Customer Name

Business Name

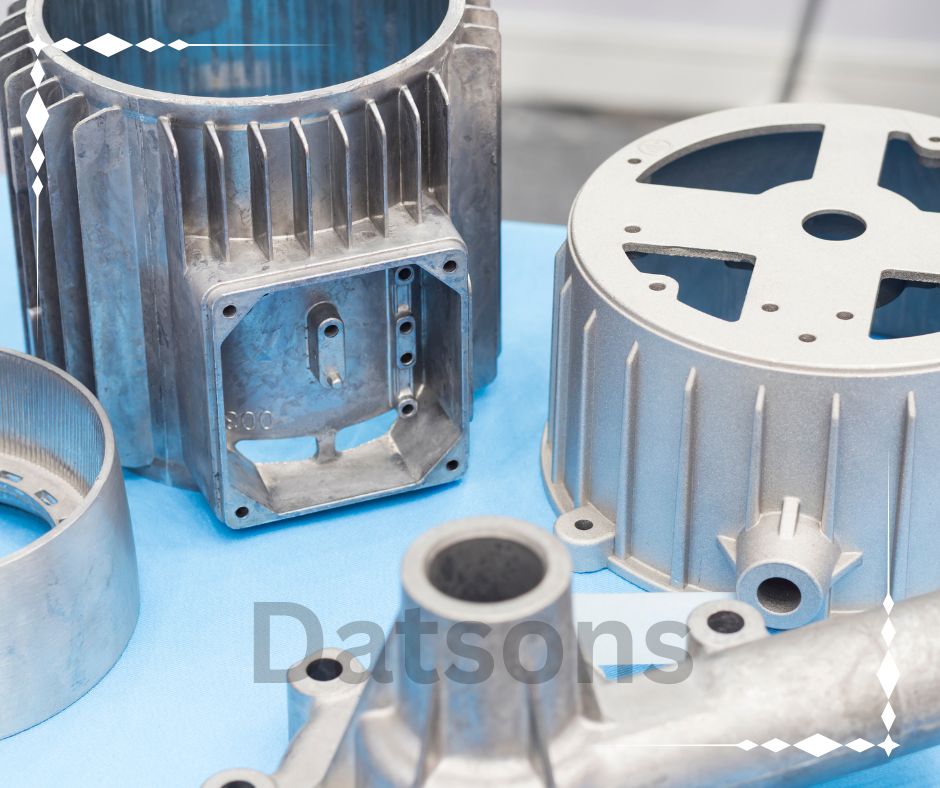

We Create That Creates

For custom tools that fits your purpose and last decades, Datsons is your go-to place.

Schedule an AppointmentCall for Service Today