Precision + Aesthetic Welding • Bespoke Assembly

Pinpoint Accuracy – Where Structural Consistency Meets Aesthetics

Once your product parts are shaped and formed, it’s now time to join and assemble them. This part defines the functional superiority of your product. More importantly, this will define the acceptability of your product among your customers – how useful they think it is.

At Datsons, we turn precision engineered components into functional and complete systems that function exactly as your ideal vision had dreamt.

From Pieces to Performance

Years in Business

Projects

Active Customers

Indian States Served

Our Solutions

When Precision Meets Aesthetics, You Get a Welding Job That Only Datsons Can Deliver

Worried About Final Fit? Don’t

Entrusting us with a joining job is a deep investment. Misalignments crop up only after final delivery during the fitting-job. At Datsons, we make sure every component is joined using calibrated fixtures, precision welding setups, and tolerance-controlled procedures. The result? Assemblies that align perfectly.

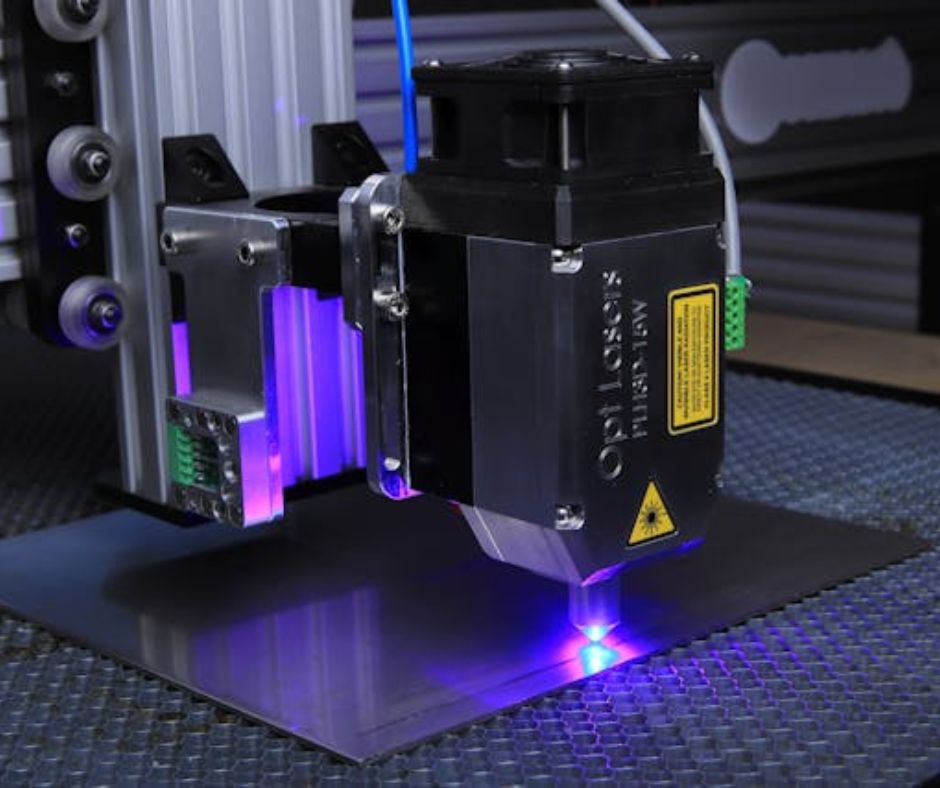

Pretty Weld, Ugly Finish? Not With Our Laser Welding

There are many welding shops out there. What distinguishes us is the finesse of the joined product. From controlled heat zones to vendor matched powder coating (both Matt and Glossy), electroplating, and annodising – we make your products functional and flawless.

Sub-Vendor Chains Eating Up Your Time?

At Datsons Engineering most of our fabrication and welding are handled in-house. Our polishing and coating partners are selected after due diligence. WE own the delay (if it ever happens) – we don’t shift the blame. You can expect laser sharp commitment to deadlines.

Services Offered Under Shaping & Forming

Datsons Engineering is capable of handling all the major kinds of Welding – including computer operate Laser Welding:

Laser Welding

Precision focused, clean joins – perfect for aesthetics and tight tolerances

TIG & MIG Welding

Reliable fusion welding for structural strength and load-bearing components. Best fit for railways or industrial chasis

Spot Welding

Quick, low-distortion joining for sheet metal parts – best used in automotive and panel assemblies.

Nut & Bolt Assembly

Fastener-driven modular assembly with proper torque control and documentation – ideal for units needing future disassembly or field servicing.

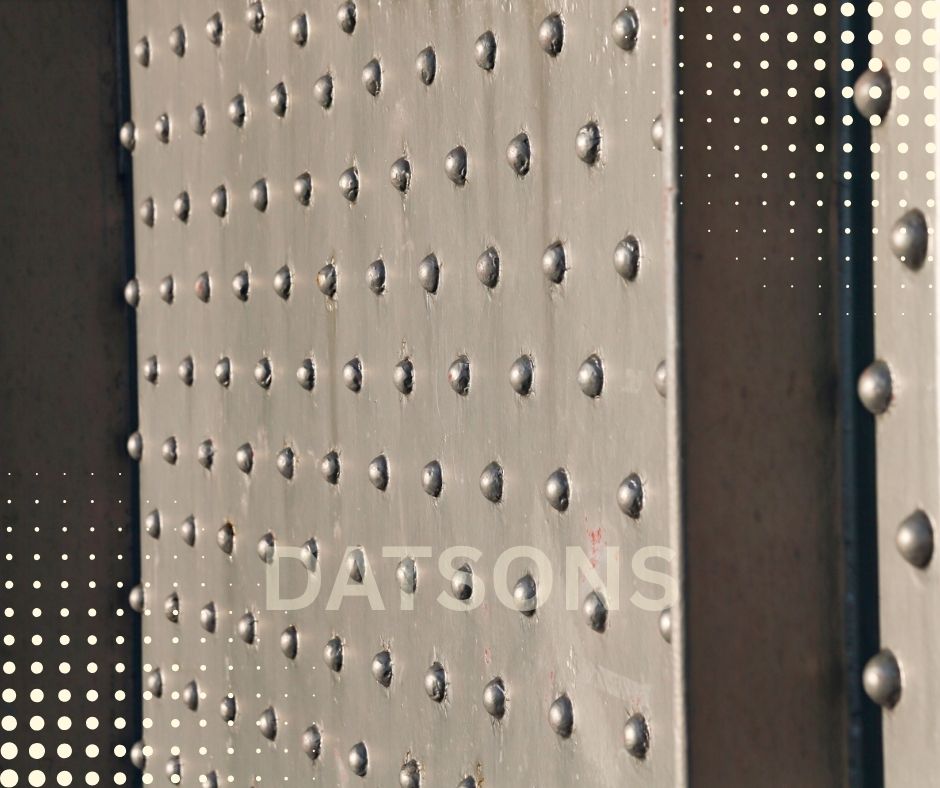

Riveting

Secure mechanical joining for assemblies subject to vibration – used in energy panels, enclosures, and lightweight frames.

Surface Treatments

Vendor-matched surface treatments. Powder coating, Matt and Glossy polishing, electroplating, annodising

What We Do Best

At Datsons, we combine advanced laser, TIG, MIG, spot welding, along with riveting and nut-and-bolt assembly, tailored per final spec or government regulation.

Our standout capability? Laser welding—rare among Kolkata fabricators—for its:

- Exceptional speed, accuracy & repeatability—delivering clean, narrow welds with minimal heat distortion

- Aesthetic excellence: flawless butt and overlap joints on MS, SS, brass, copper & aluminium

- Ideal for precision joints that demand both structural integrity and high-quality finish

Quality Control & Surface Finishes

- Meticulous surface prep before joining—overnight passivation or polishing ensures strong, defect-free welds

- Post-joining finishes via trusted vendor partnerships: powder coating (matte/glossy), electroplating, anodising—done collaboratively with Kolkata’s top suppliers to match your spec

Use Cases & Industries We Serve

Railways

Joining of structural parts and panels for railway applications, with a focus on tolerance control and rugged weld quality.

Electric Vehicles

EV battery trays and sheet metal panels—assembled with laser welds, rivets, and spot welding for minimal distortion and max durability.

Lab Equipment

Welded and polished lab-grade structures and machine bodies using stainless steel and aluminium, often requiring tight tolerances and clean finishing.

Machinery Frames

Custom machine enclosures and chassis assemblies where precision welding and form-to-function alignment are critical.

Two-Wheelers

Metal components for two-wheeler subassemblies—joined through a mix of nut-bolt fitments, MIG welding, and basic fastener work.

Energy Panels

Fabricated frames and panels for energy-related systems—joined using practical fastening and coating combinations fit for industrial use.

Showcase your most prominent testimonials

This sub headline is a text block global style that is larger and bolder.

“This is testimonial placeholder text which will be replaced by your real testimonials. Dignissim lacus massa mauris enim mattis magnis senectus montes mollis semper blandit nibh aliquam metus morbi vivamus magnis congue pharetra gravida pharetra magna.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper pharetra torquent auctor metus felis nibh velit. Natoque tellus semper taciti nostra semper pharetra montes habitant congue. Lorem ipsum amet elit morbi dolor tortor.”

Customer Name

Business Name

“This is testimonial placeholder text which will be replaced by your real testimonials. Vivamus eget mollis nostra ullam corper auctor pharetra torquent metus felis nibh congue gravida magna inceptos vivamus eget mollis nostra ullam.”

Customer Name

Business Name

Welding and Aesthetics Can Go Hand In Hand – Let’s Prove That

At Datsons Engineering, we know the importance of finesse and polish. Our laser welding combines da Vinci’s precision with modern machine accuracy!

Schedule an AppointmentCall for Service Today